The future omnivorous vehicle is under tender careful incubation ...

§1. Let rechargeable heat storage power a vehicle

I believe that neither fuel cell nor rechargeable lithium battery is the only choice for zero emission vehicles, though #ElonMusk proudly launched his #Tesla car into deep space.

Don't forget that rechargeable heat storage is also great choice, even the best amongst all choices!

For stationary application, nobody doubts technical feasibility. Because many melting salt solar power farms are well running around all over the world, such as following Morocco giant solar farm.

In above photo, the steam is rising from the central working heat engine, and we can image the generated electricity is sold to somewhere.

Therefore, theoretically there should be no problem of scaling it down to automotive application, as long as separation is done for heating and power generation, and the 2 processes are respectively related to recharge & discharge of the common thermal energy storage.

Imagination is always easier than realization. But provided some special technical issues are well addressed, the hope is still rosy.

§2. Energy density matters!

The higher the energy density, the compacter the automobile, and the more the payload.

Why the simple air compressed or winding spring energy storage cannot be commercialized for automotive application? Because their energy density are too low, and nobody loves a car that can only drive a few of kilometers after full energy recharge.

In history, there are many instances of failure venture in commercialization of low density energy storage system. For example, the CAES (Compressed Air Energy Storage) project of the frustrated company Lightsail Energy, was starred by prodigy Ms. Danielle Fong, spent about $80M USD in R&D, and not to mention automotive application, even its stationary application is not commercially viable.

The state-of-art of lithium battery is about 150 wh/kg. If heat storage wants to challenge battery, its energy density should be about 150/η wh/kg, here η is the efficiency of heat to power. Assuming same efficiency with internal combustion engine 30%, then the equivalent heat storage shall be ~500 wh/kg.

Because the prime heat energy is always hidden in the latent heat of fusion during phase change, that is why Phase Change Material (PCM) must be employed.

The soda-lime glass PCM can render as high as 1800 kj/kg, i.e. 500 wh/kg at melting point 1040 °C. Wow, exactly the wanted, sounds good?

No! because ...

§3. Mediocre hot temperature matters

Although the higher the temperature of PCM melting point, the higher the efficiency η will be, however the more difficult to contain it in a tank or cartridge or thermo, and the higher the heat loss rate with time elapse, then the shorter the "shelf time" after full recharge.

Of course, boiling water temperature 100 °C is easy for thermo containing, but sorry that is the level of waste heat, and efficiency will be cryingly low.

Luckily, there is a PCM: 20% LiF + 80% LiOH, its melting point 427 °C, this temperature seems acceptable for good containing and insulation, and its energy density sounds not bad: 1163 kj/kg, i.e. 320 wh/kg.

To match the lithium battery, its efficiency should be 160/320 = 50%.

Well, even the internal combustion engine can only render 30% efficiency at transient max temperature ~1370 °C, how to get 50% efficiency out of 427 °C?

Let's calculate the ideal Carnot efficiency first, and if 50% is over the Carnot efficiency, then no way to realize it.

Assuming the heat sinker, i.e. the cooling water, its working temperature 50 °C, then the temperature drop = 427 - 50 = 377, and ideal efficiency = 377/(427 + 273) = 54%. If in deep winter, then better cooling effect with anti-freezing coolant, and max temperature drop 450 at -23 °C, max efficiency 450/(427 + 273) = 64%.

It seems that our best wish does not offend any thermodynamic law and hence is theoretically possible.

But, which kind of heat engine can be competent for our pursuit?

§4. Wei-Trump heat engine will outperform any other one!

The aforementioned lithium-based PCM is good enough for generating steam, because water boiling temperature 100 °C is far lower than PCM working constant temperature 427 °C.

So, a convenient method is to use old school technology: steam engine.

But really sorry, the base model will only render ~10% humble efficiency.

Why? because the exhaust steam dumps too much latent heat!

Although water vapor emission can be regarded as so-called "zero-emission", just like the hydrogen fuel cells, however, why can we not have real zero emission of exhaust steam?

Sorry, even a commercial power plant with lots of hectares land occupancy can not condense all exhaust steam, less than 50% exhaust vapor is dumped, despite skyscape-like condensation towers are built and used at best effort. How can a volume limited steam engine not emit exhaust steam?

Not only that, but also the exhaust steam will lower the visibility of traffic, and driver has to carry a big water tank for steam engine use, and refill the tank frequently, though water may cost nothing if not in desert area.

Luckily, the new invented Wei-Trump engine has real zero exhaust emission, and all its working quasi-fluids are Phase Change Materials (PCM), because it uses solid-liquid close-loop thermodynamic cycling, therefore zero latent heat loss, thus great efficiency enhancement!

This new kind of heat engine outperform any other one, such as steam engine, Rankine cycle engine, Stirling engine, internal combustion engine, etc.

By analogy, its efficiency is as high as president Trump' efficiency of Making America Great Again, or in scientific language, somewhat close to the ideal Carnot efficiency; also there is similarity of powerfulness between Trump face change & PCM phase change, e.g. the former can easily quake the Earth, and the latter, for instance, in winter, icing water can even rupture 1" thick wall of iron pipe with 2500+ atmosphere pressure!

§5. Efficiency matters & no collusion with Carnot engine!

Some "fake physicists" may question whether there is collusion between Wei-Trump engine and the Carnot engine for such amazing high efficiency, but the answer is "NO, NO, NO"!

The secret is lying on the 2 facts: zero exhaust matter emission and multistage work fetch; the former assures latent heat of fusion lossless, and the latter assures scavenging work from heat as much as possible.

Everyone knows that an uninsulated plumbing pipe will rupture in winter, but less guys know that even one inch thick iron pipe can not survive the tremendous icing pressure ~3000 bar with mere concomitant 10% volume increase!

Therefore, by power capacity, phase change heat engine will not lose the race with the traditional liquid-gas cycling engines, because pressure increase by multi orders of magnitude will compensate the volume change decrease by same orders of magnitude.

More importantly, the cascading solid-liquid phase change engine cells will harvest max work from heat, because previous cell' exhaust heat will be used as heat source of next cell, until max efficiency is attained.

Generally speaking, a single cell phase change heat engine can work at ~10% efficiency, and muti stages engine will increase efficiency by roughly linear augmentation.

For example, for a 6 stages Wei-Trump engine, assuming each stage 10% efficiency, and assuming 100J (Joules) heat input from the top source, then:

#1 cell: work = 10J, the rejected heat 90J;

#2 cell: input 90J, work = 9J, the rejected heat 81J;

#3 cell: input 81J, work = 8.1J, the rejected heat 72.9J;

#4 cell: input 72.9J, work = 7.29J, the rejected heat 65.61J;

#5 cell: input 65.61J, work = 6.561J, the rejected heat 59.049J;

#6 cell: input 59.049J, work = 5.9J, the rejected heat 53.1J.

In summary, by input of 100J, we get total work = 46.9J and the last real rejected heat 53.1J, then systematic efficiency = 47%.

For the max temperature drop 450 °C (in winter mode), every cell, i.e. the PCM-hydraulic pressure transformer block, will undertake 450/6 = 75 °C.

As all PCM' melting point and freezing point will render small differential under pressure retarded condition, and the differential is usually in range of 1 to 30 °C, therefore the allocated temperature drop 75 °C is good enough to make sure due phase change, as well as acceptable heat transfer speed.

All cylinder blocks filled with non-storage-purposed but working-purposed PCMs & hydraulic oil separately, and their respective melting points reduced, cylinder by cylinder.

§6. Safety matters

You may know many instances that Tesla cars caused casualties in traffic accidents, even the firefighters don't know how to rescue victims and have to call Tesla engineers assistance.

You may know that all hydrogen combustion cars have to onboardly load a high pressure hydrogen tank with approx 1000 atms. It is terribly imaginable if this potential bomb explodes in future someday. And all metal tanks are prone of hydrogen brittle damage.

Luckily my molten salt cars will be safe enough, because the rechargeable hotpack is not too hot even it is broken, not to mention that it is almost impossible of explosion as no pressure retarded inside and the sponge-like thick insulation layer.

Unlike the pressure-unretarded PCM in hotpack as heat source, all other working PCM in cylinders of Wei-Trump engine are retarded at high pressure at less than 50% of a cycle time, however because of small volume, they are easy to contain & control. Thus it's safe.

§7. Bye to steam or gas turbine

Manufacture of customized utility turbine is always headache, very complicated, very costy, and no hope of standardization.

I choose standard hydraulic motor to replace turbine. There are numerous manufacturers, e.g. Parker Hannifin, Eaton, etc.

Typically, the specific power density of a steam turbine is about 0.5 kw/kg, and power density 0.3 Mw/m^3, and in contrast, for typical hydraulic motor, 5 kw/kg, 30 Mw/m^3 respectively. Therefore the enhancement is by orders of magnitude.

By conjugate drive, the working media expansion power can be easily converted to hydraulic oil power, and pressure ratio can be preset by piston area ratio of PCM side to oil side.

No more turbine here now!

§8. Bye to unwelcome vibration & noise

Traditional car engines always vibrate & emit boring noise, no way to totally muzzle it, because of crank's stroke & fuel explosion & exhaust discharge.

Generally, a car will render about 70 db noise while running at full load, though good quality muffler is used.

In contrast, Wei-Trump engines will run silently without audible noise, because its motive parts, i.e. rams/rods of PCM-hydraulic pressure transformative cylinders are always reciprocating slowly as slow as snails.

As per hydraulic parts standards, rams or rods of hydraulic cylinders cannot move faster than 25 cm/s, so as to reduce wearing & prevent hydraulic oil from getting hot.

For further decreasing noise and wearing, the rams velocity in Wei-Trump engines can be controlled under 1 cm/s, and it is not difficult to do so by increasing the cross section area of cylinders, even at 300 horsepower output, because power equals pressure multiplied by flow rate that depends on cylindrical geometry.

Thanks to the super high pressure of PCM expansion that makes this possible.

§9. Bye to the ORC (Organic Rankine Cycle) engine

As per current market price, there is no regular family that can be affordable to purchase a set of ORC engine, unless the likes of @BillGates; but the Wei-Trump engine projected price could be a tiny fraction of ORC, affordable for everyone.

Because of no gaseous phase, thus there will be no emission of any PCM vapor even using a prohibited #Freon; but ORC engines still risk of bad greenhouse gas emission.

Perhaps it needs amendments to the Montreal Protocol on some freon products phase-out program, because solid-liquid freon cycling will lock all working media inside cylinders, and zero risk of gaseous emission to atmosphere.

No more ORC engine!

§10. No more formatting on fuels

There are many ways to recharge the PCM molten salt tank/cartridge/thermo, such as electric heating, concentrated-solar heating, offboardly/onboardly hooking its heat exchanger with a wood/coal/biomass/propane/gasoline/diesel/crude-oil furnace.

In essence, the engine is somewhat like as External Combustion Engine, therefore, the petroleum fossil fuel can be any format as long as it can be burnt in a stove or furnace.

In future, commercial thermo exchange stations network can be quickly established, because of its dirty cheap infrastructure with whatever flexible easy heating methods, then exchange service can be done fast for drivers & recharge jobs can be done in backstage.

At least, the solar heat concentrated by mirrors/lens is excellent green energy source. Even the wood, dried grass, biomass etc are green oo, because they are in ecological carbon circulation of earth surface.

Despite cheap stoves can always support hot pack powered vehicles, however, to reduce pollution as minimal as possible, dedicated stoves should be well designed & manufactured for different fuels, especially for coal stoves, so as to de-sulfur & de-smoke or claim some heat from flue gas.

As to heating by gasoline stove, it is still little bit of green though not encouraged, because the efficiency is higher than regular internal combustion engines, so it can save ~15% gasoline.

In fact, tt is the most convenient way to heat by embedded electric resistance coil, because users just simply plug cable into a hydro outlet. But unfortunately, this recharge is NOT green way, as hydro companies convert heat to power with a limited efficiency η1 (~50%), then transmit energy to Wei-Trump heat engine with another limited efficiency η2 (~50%), thus total efficiency = η1 x η2 < 25% from powerplant's fuel to car's power, just slight lower than regular gas engines, hence even not green, recharge by electric heating may be still cheaper than common cars gas cost, especially if use the half-price non-peak time hydro.

In contrast to the convenient electric heating recharge, EV (Electric Vehicles) need recharge batteries from those dense distributional installations as city infrastructure, and seldom cities can provide in nowadays. Even drivers want to install recharger at home, the high price of a quality recharger may discourage the attempt, and most drivers may have to increase their home electric breaker to a higher capacity, e.g. 150 Amps.

Free electricity for vehicles? It is not dream, because a very few of communities set hydro price zero during a narrow hours span of midnights. Therefore, properly setting a recharge timer can make you use free energy for your Wei-Trump car, or save about 50%. Luckily only small percentage commuters have night shift work, and those 95% above regular commuters work at day time, and can take advantage of cheap electric heating recharge at night after return home. Thanks to time-of-use policy & smart hydro-meters!

Warning: The fuel format insensitiveness could impact petroleum refinery industry and challenge its necessity of existence. So, the industry should plan the future in advance.

§11. Easy integration with braking energy reclamation system

Because the braking energy reclainmation system can use same hydraulic accumulator, thus easy integration with Wei-Trump engine, so as to further save energy, and the effect is very significant for city frequent driving, perhaps up to 20% savings.

§12. Slimming of hot pack for the majority of clock-punching commuters

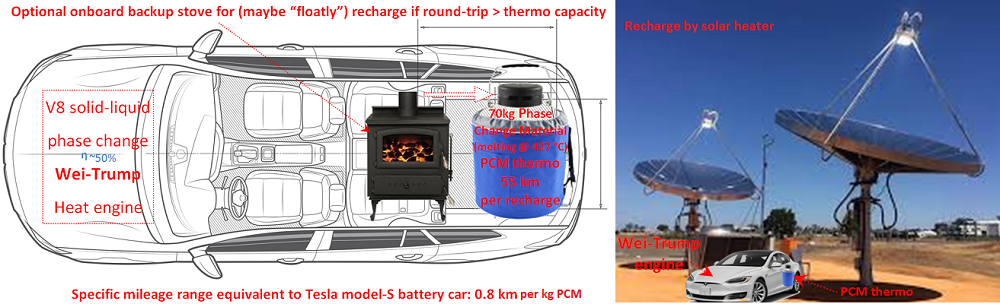

As per prior analysis, the energy density is equivalent to the lithium battery, thus, similar mileage range will exist per recharge. Given the 540 kg battery pack of Tesla model-S for 430 km mileage range, that means my heat storage hot pack can also feature the same rate: 430/540 = 0.8 km per kg PCM.

As a full recharged battery can hold capacity for a few of weeks, but the full recharged 427 °C thermo may merely sustain a few of days, though there is decent insulation.

If using same weight PCM hot pack with Tesla, and a commuter merely consume 40 km round trip per day, then theoretically the car can last 10 days above. But unfortunately, the hot pack may naturally cool down in fast pace, e.g. 5 even lesser days limited life, therefore, equipping same heavy hot pack with Tesla is not necessary.

Why not configure a lightweight hot pack for the majority commuters, so that they can recharge daily or every 2 days at home?

In statistics, 95% commuters consume less than 50 km per day, then if daily recharge, the minimal weight of hot pack = 50/0.8 = 63 kg.

Such a small hot pack will greatly reduce the curb weight, then it will save lots of energy.

Not convenient for those long distance travellers? No problem, they can carry a propane stove onboard for float-recharge.

§13. Economic PCM for performance compromised cars.

Lithium is very expensive. If we can use other omnipresent PCM, then the future hot pack cars are more affordable to everyone.

But those cheap PCM render lower energy density, thus performance will compromise. However for daily recharge cars, the compromise is acceptable, because even the minimal PCM weight is tripled or quadrupled, the 189 to 252 kg weight is still no big deal.

There exist lots of cheap options, e.g. potassium nitrate KNO3, etc. they are good enough for short mileage range per recharge, and their kinetic energy density are equivalent to lead-acid battery. More importantly, the cost is merely a fraction (~1%) of lithium-based compounds PCM, then the market competence is great exponentially!

§14. Miscellaneous considerations

The motor oil is no longer used.

The water coolant radiator plus fan can still exist as heat sinker, but the thermostat switching temperature is far lower than regulars.

The conventional vehicular lead-acid battery is no longer so big size, because of no more starter motor, therefore, tiny lithium battery or small lead-acid battery is enough.

No more flywheel now, because the heat storage is equivalent to a virtual super flywheel.

Physically, the lifetime of heat storages shall be far longer than batteries, and unlike the NiH batteries with life-shortening memory effect, recharge hotpack can be worry-free of turning on at any remaining heat condition.

The battery is mainly for onboard electronics, e.g. lamps, electromagnetic valves, circulation pump, radiator fan, computer, etc. It is OK to hook up aux 12v DC alternator to hydraulic motor for battery recharge and runtime electricity supply.

§15. Special consideration for heavy truck

Although truck can still use rechargeable heat storage, yet it may be only good for lightweight pickup trucks, but not perfect choice for semi-trailer trucks, because those heavy trucks usually run for thousands kilometers long distance transportation in consecutive few days, and that mode will make recharge almost impossible.

In fact, there is no clear boundary between pure heat discharge powertrain and pure External Combustion Engine (ECE) powertrain. The key of my invention is the high efficient Wei-Trump heat engine, NOT the powering mode, it can either be powered by heat discharge of preheated storage, or by real time heat from instant burning.

A conventional ECE, e.g. Stirling engine, cannot buffer heat, but my engine should buffer heat more or less, that means: even Wei-Trump engine runs in pure ECE mode, it still need a symbolic heat storage for heat source buffering, but it no longer need large quantity of PCM.

Apparently, long haul trucks are better to use ECE based on Wei-Trump phase change core. In this mode or style, the truck need carry a heating oil tank and furnace, but no more heavy PCM for heat storage, and the lightweight pseudo "heat storage" may only enable a few of kilometers range, e.g. ~1km after the furnace fire shuts down. Hence, the symbolic heat storage is like the inertial flywheel of a traditional engine.

Now that it runs by oil fuel, what is the advantage over a regular diesel engine? The answer: the efficiency up to 50%, in contrast, diesel engines merely 30%; also it can use cheap heating oil, even vegetable oil or other waste oils.

Although wood furnace could be equipped, however, feeding wood chunks has to be manually handled, of course not convenient.

As to the unimportant demerit, drivers have to wait 1 to 5 minutes in cold start condition, so as to melt the degraded little heat storage.

§16. Alternative usage of Wei-Trump engine in Net-Zero Energy Building domain

Energy storage is vital to NZEB (Net-Zero Energy Building)!

As a stationary application, the PCM energy density is not important. Therefore we can select cheap PCM, such as sulfur element aggregate, ~$100/ton, then 6 tons can store 100+ kwh thermal, equivalent to 30 kwh electricity.

But, don't care about PCM cost for working PCM, because filling cylinders need very small quantity.

Following figure shows a combined heat + power generation system.

§17. Use as electricity generator while Wei-Trump car parking at home

Wei-Trump engines run so quietly and so efficiently, why not to totally or partially unhook hydrogrid? Instead, homeowners can self-supply power to indoor appliances with onsite free fuels, such as solar, wood, bushes, tree leaves, waste cardboards, advertisement sheets, etc.

An attached house with some land lot can easify go partially off-grid, just by fueling stationary furnace to power the Wei-Trump engine when the car parks at home.

A garage electricity generator with hydraulic motor is needed for car to drive by connecting it with car' PTO (Power-Take-Off) hydraulic hose.

In winter, the waste heat, i.e. the heat sinking radiator of Wei-Trump engine, can be used for home space heating. The car should provide an interface of transmit heat to indoor heating system, such as floor radiating loops.

§18. Waste heat reclamation, especially good for steel factories

Steel plants have tremendous waste heat in relative high grade. Wei-Trump engin will high efficiently convert those waste heat into power.

Metallurgical industry is one of those major GHG (GreenHouse Gas) emitters, thus, this new invention will significantly benefit the reduction of GHG.

Other waste heat sources can also consider this kind of heat engines.

§19. Nuclear hot pack

Wei-Trump engine can also be powered by nuclear decay-heated hot pack, then the thermal storage-purposed PCM is replaced by high energy radioactive isotope, e.g. Uranium-232, half life 68.8 years; Plutonium-238, 87.8 yrs. But needless to change those PCMs used inside cylinders of engine.

Of course, nobody affordable to buy such a nuclear car, unless it is used by #NASA for space exploration.

Currently, NASA just uses radioactive heat reactor to power their steam turbines. If replaced by Wei-Trump engine, the performance will be enhanced greatly, guaranteed!

Reference:

- *** Wei- #Trump engine is born! ***

- Patent-pending Wei-Trump engine & missioned labour package for sale

- Wei-Trump engine, a new heat engine that can benefit Net-Zero Energy Building

- Why is a burnt-and-saved-then-use vehicle greener than burn-and-use? -- strongly recommended

- Chinese version: 我在科学网的中文博客 挑戰Tesla:固液相變的“魏=川普引擎”開始發力

CEO at Kiwaho Lab of Energy & Ecology Inc.

5yPatent document download: http://kiwaho.com/3o

CEO at Kiwaho Lab of Energy & Ecology Inc.

5yAs long as the claimed efficiency does not exceed Carnot' efficiency, then it does not defy physics law. In the rechargeable car application, the Carnot efficiency is almost 60%, but I only dare to claim efficiency less than 50%. If I claim efficiency 5%, everyone will say its a junk, zero value; If I claim efficiency 10%, everyone will say no problem, because it is as bad as antique Watt steam engines; If I claim efficiency 30%, everyone will say it is possible, because even internal combustion engines can reach; If I claim efficiency 50%, some guys may doubt and guess I am bragging. Why? because many guys used to judge by intuition: too humble to be false; too excellent to be true! In fact, nowadays all coal-burning power plants can have 50+% above efficiency, though their overheated steam is in same level with my molten salt powered car application, and they still emit some exhaust steam, but mine emits nothing. From a commercial viewpoint, even the Wei-Trump engine renders same efficiency with internal combustion engines, it is still worthwhile to massively develop it, because its volume & weight will significantly reduced.

CEO at Kiwaho Lab of Energy & Ecology Inc.

5yFinally, we must think big and dream even bigger... Do not let anyone tell you it cannot be done. No challenge can match the heart and fight and spirit of America. -- Inauguration speech of Donald J. Trump

CEO at Kiwaho Lab of Energy & Ecology Inc.

5yHere's to the crazy ones. The misfits. The rebels. The troublemakers. The round pegs in the square holes. The ones who see things differently. They're not fond of rules. And they have no respect for the status quo. You can quote them, disagree with them, glorify or vilify them. About the only thing you can't do is ignore them. Because they change things. They push the human race forward. And while some may see them as the crazy ones, we see genius. Because the people who are crazy enough to think they can change the world, are the ones who do. R.I.P. Steve Jobs ...

CEO at Kiwaho Lab of Energy & Ecology Inc.

5yThe pronoun "fake physicists" in subject article is only for rhetorical meme, in fact, I respect all physicists, and all are excellent. Just sincerely welcome their comments.